[ad_1]

Backside line: That isn’t a typo: a 2nm-capable fab may price round $28 billion. In reality, prices all through the 2nm improvement and manufacturing course of might be elevated because the instruments might be extra advanced and the expertise wanted might be dearer. One saving grace is likely to be AI-enabled EDA instruments that may streamline processes and assist scale back prices.

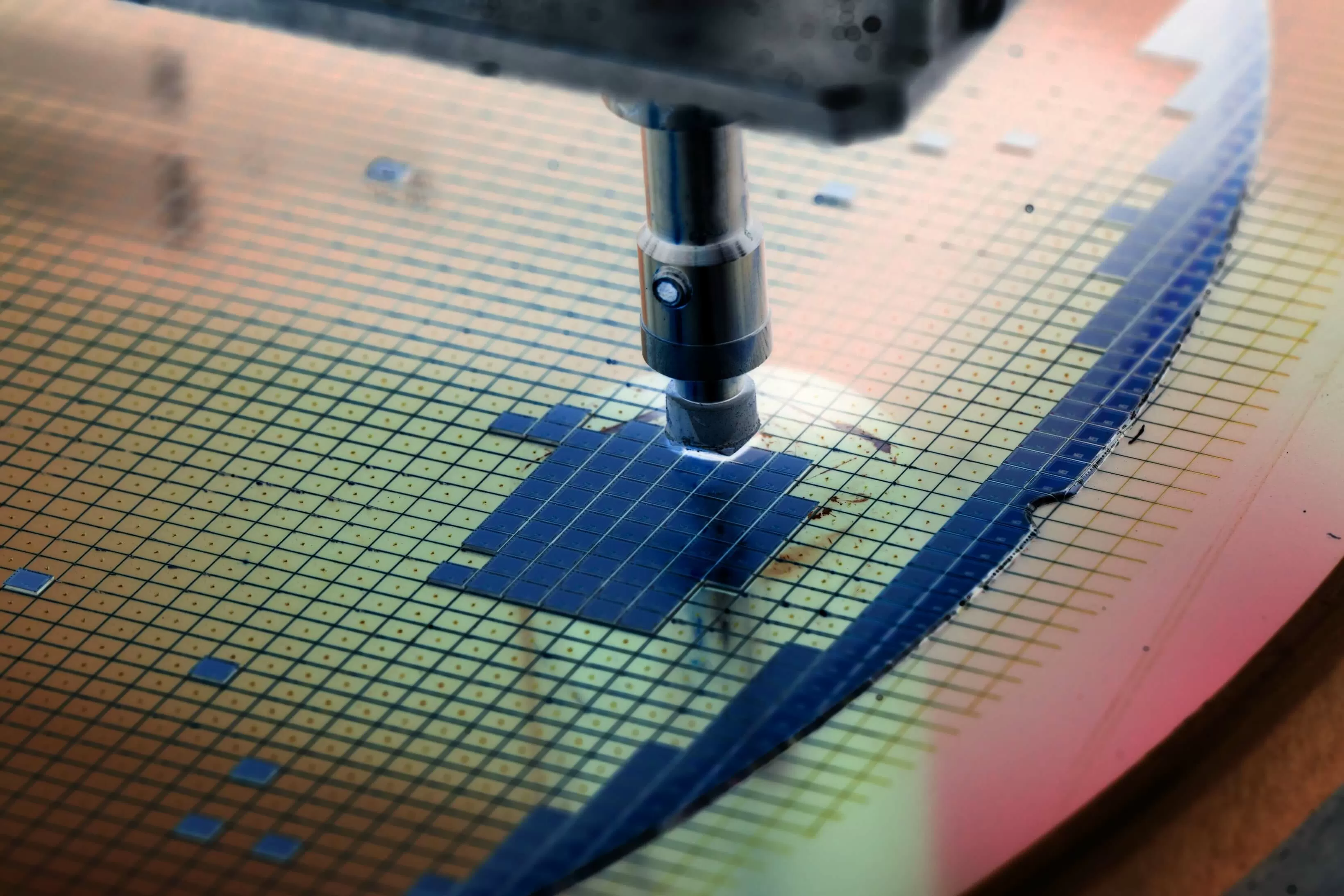

A 2nm-capable semiconductor fabrication plant that has a capability of fifty,000 wafer begins per 30 days, or WSPM, will price round $28 billion, in response to consulting agency IBS. That’s $8 billion greater than the fee for a 3nm fab and only one illustration of the exponentially increased bills that corporations can anticipate because the trade strikes to the subsequent era of chips.

To be exact, 2nm chip prices will rise round 50% in comparison with 3nm processors, IBS says, that means that corporations akin to Apple must spend $30,000 to course of a single 300mm wafer utilizing TSMC’s N2 fabrication course of when it’s launched within the subsequent few years. Probably, although, there’s some wiggle room in these numbers, doubtlessly bringing down the anticipated excessive price of those chips.

There are in reality quite a few approaches that semiconductor corporations can take and an array of design choices they’ll make through the pre-construction, building, and operations phases that may materially alter the ultimate price of the fab.

Additionally learn: How CPUs are Designed and Constructed

To make sure, the prices of chip improvement are nothing to scoff at. Software program improvement alone accounts for $314 million and verification is one other $154 million, IBS figures present. Additionally, designing chips on the 2nm node requires specialised expertise, which is in brief provide. Then there’s additionally the elevated use of photolithography, a course of used to create the patterns on a chip’s floor.

The smaller the options on a chip, the extra exact the photolithography course of must be, thus driving up the price of the gear and the supplies used within the course of. And that 2nm-capable fab that may clock in at $28 billion? Driving the $8 billion price differential is the elevated variety of EUV litho instruments required to take care of a 50,000 WSPM capability.

However even IBS acknowledges that there are nuances behind such figures and the evolving panorama of chip design. It has estimated that it will possibly price an organization $725 million to construct a large 2nm chip from scratch. However that’s by an organization with out pre-existing mental property and the truth is many semiconductor corporations, significantly startups, pursue extra environment friendly methods.

IBS additionally factors out that the position of AI-enabled EDA instruments is turning into more and more essential in chip design, streamlining processes and lowering prices by automating advanced design processes and optimizing chip efficiency.

[ad_2]

Source link